AHX440 General Purpose Multi Corner Insert Type Face Milling Cutter

The existing AHX series has received a favorable reception in the market place as a face milling cutter with its excellent economy and efficiency through the adoption of heptagonal double sides insert (14 corner inserts). To efficiently cover a wider range of work materials and applications the smaller insert type AHX440 has been added.

Features of the AHX440

- Double positive cutting edge geometry offers lower cutting resistance for improved machining efficiency.

- High rigidity by increasing the thickness of the inserts enables high feed machining.

- The unique conical insert seat holds the insert securely. The outer edge of the insert is not in contact with the body, thereby controlling abnormal insert breakage and body damage if sudden fracturing does occur.

AJX Series of High Feed Radius Milling Cutters

The existing AJX series of has a proven track record for high feed, high efficiency machining.

To complement the existing range, PVD coated carbide grades MP7130 and MP7140 for machining stainless steels have been added. Additionally a new JL chipbreaker featuring a sharp cutting edge with low cutting resistance has also been added.

Features of the JL breaker for milling difficult-to-cut materials and the new PVD coated carbide grades MP7130 and MP7140

- The low resistance JL chipbreaker edge design reduces cutting heat and helps to control insert wear.

- Newly developed Tough-Σ Technology (accumulated Al-Ti-Cr-N based PVD coating) with multi-layering of the coating prevents any cracks penetrating through to the substrate and dramatically improves fracture resistance.

- Through the use of TiN based components, the PVD coated carbide grades MP7130 and MP7140 prevents flank wear at the depth of cut line that can occur when machining stainless.

APX3000 Multi-functional Indexable Insert Cutter Series

APX3000 is an indexable insert cutter with the capability for multi-functionality, including ramping and profile machining.

To cover a wider range of applications, new cutter bodies for deeper applications with inserts positioned on peripheral cutting edge have been added to the APX3000 series.

Features of the cutter bodies

- Increased rigidity is possible because of the large amount of back metal designed into the body.

- The large rake angle provides less resistance and reduces heat generation during machining.

- By arranging inserts on the peripheral cutting edge of shank type cutters, depths of cut from 28-55 mm can be achieved.

New BC8220 PVD coated CBN insert grade for turning hardened steels

New BC8220 grade has ideal balance of wear and chipping resistance by adopting a newly developed CBN substrate featuring toughness and crater wear resistance. This enabled longer tool life when turning hardened steels.

Main feature of BC8220

- BC8220 utilises a new, specially developed, super multi-layer ceramic PVD coating. The high level of both chipping and wear resistance is achieved by improved adhesion between the substrate and coating

- The new CBN substrate contains a new ultra-fine grain, heat resistant binder. This suppresses both chipping and crater wear that promotes longer tool life.

- Can be used over a wide range of applications, from high speed through to heavy interrupted machining

BC8100 Series for High Hardened Steel Turning

BC8100 series delivers substantially better wear resistance and high cutting edge toughness by adopting a newly developed coating and CBN substrate. It achieves high efficiency during general use and provides extended tool life that requires fewer tool changes. Additionally BC8100 series is especially effective for interrupted machining of high hardened steels that are typically used for automotive parts.

BC8100 series has now been further expanded to include new types of honing and wiper inserts.

Features of items added for BC8100

- TH type honing for improved fracture resistance is applied to the cutting edge of the BC8120 and BC8130 grades used for medium to heavy interrupted cutting.

- GH type honing for improved fracture resistance is applied to the cutting edge of BC8110, BC8120 and BC8130 grades for light interrupted cutting.

- A wiper insert for continuous cutting, the FSWS type is added to the BC8105, BC8110 and BC8120 grades for medium to heavy interrupted cutting.

ISO turning inserts MP9000/MT9000 series for difficult-to-cut materials Addition of the RCMT round type positive insert

The MP9000/MT9000 insert series is ideal for difficult-to-cut material applications such as machining of titanium and heat-resistant alloys as well as corrosion-resistant alloy components used in the aerospace and medical equipment industries.

Improved fracture and welding resistance reduces edge breakage and prevents the problems usually associated with machining difficult-to-cut materials. The addition of the RCMT round insert RCMT further expands the areas of application for the series

Main features of the MP9000/MT9000 series for difficult-to-cut materials

- The high Al-rich (Al,Ti)N single layer coating provides stabilization of the high hardness phase and succeeds in dramatically improving wear, crater and welding resistance.

- MP9005 is a top-quality grade focusing on wear resistance.

- MP9015 is the first recommendation for general applications.

- MP9025 prevents severe damage for increased stability.

- The MT9000 series is a range of un-coated cemented carbide grades such as MT9005, with unmatched resistance to heat and plastic deformation that can handle high-speed cutting. Additionally, the range includes MT9015 featuring a sharp cutting edge but with excellent wear and fracture resistance.

- RCMT round type geometry with a strong cutting edge that provides excellent finished surfaces.

GY Series, Grooving System

The existing GY series has received a favorable reception as a grooving system that has a wide selection of holders and inserts available for diverse grooving applications, such as external, internal and face grooving.

This new insert for aluminium alloy machining enables GY series to expand its coverage over a wider range of workpiece materials and application

Features of the insert for aluminium alloys for the GY series grooving system

- An ideal small chip shape is formed by narrowing the width of the chip breaker.

- The large rake angle realises low cutting resistance.

- The sharp cutting edge improves welding resistance.

High accuracy and rigidity HSK-T type tooling system developed for use on multi-task machines.

HSK-T System

HSK-T is a new HSK system designed for turning on multi-task machines that are compatible with HSK-A type (ISO standard: ISO12164-1:2001).

The HSK system was developed by a consortium of 17 Japanese manufacturers and registered in ISO standard (ISO12164-3:2008) under the name HSK-T type in 2008 and JIS standard (JIS B6064-3) in 2013.

High Accuracy Cutting Edge Positioning

The HSK-T type has a closer tolerance between the spindle key and tool holder keyway than the HSK-A type. This results in higher cutting edge positional accuracies. For milling, the conventional HSK-A type tools can be still used.

Open Catalog

iMX-B4WH-S 4 flutes Lollipop shape head with through coolant holes

The iMX series has received a favourable reception in the market place as a revolutionary end mill system that provides excellent economy and enables efficiency, high accuracy and rigidity by combining the advantages of both solid carbide and indexable end mills. Overall rigidity close to that of solid type end mills is realised because the clamping faces of the holder and head are both manufactured from carbide.

The iMX end mill series has been further expanded to include iMX-B4WH-S, a 4 flute lollipop shaped head with through coolant holes. It features a wide cutting edge of 240° for machining of internal curved surfaces and undercuts in 5-axis machining.

Features of the iMX-B4WH-S

- A true round ball cutting edge that extends 240º, enables multifunctional machining of internally curved surfaces and undercuts in 5-axis machining.

- The high helix edge geometry reduces cutting resistance. This results in reduced chatter and vibration even when machining with a long tool overhang.

- A stable supply of coolant is maintained even when machining components with complex geometries.

New MB4120 CBN Grade for Sintered Alloy and Cast Iron Turning

MB4120, is the optimum CBN grade choice for continuous cutting and interrupted machining when turning automotive components. Parts such as valve and oil pump components that are composed of sintered alloy can be effectively machined using the MB4120 series. This series is now available and includes both negative and positive inserts.

Features of the MB4120

- Fine CBN particles increase cutting edge toughness and the high fracture resistance allows stable performance even during interrupted machining

- The optimization of the sintering conditions strengthens adhesion between the fine CBN particles. This increases both fracture and wear resistance.

- A wide range of edge honing types are available, including a sharp edge type, a round honing style and three different types of chamfer honing.

Series Expansion - ISO Insert Series for Cast Iron Turning

MC5005, the CVD coated carbide grade for cast iron turning can perform at high speeds normally associated with ceramic grades (up to 600 m/min) and is able to realise high efficiency machining. MC5005 together with MC5015 are designed as coated grades that are able to reduce costs when machining cast iron parts. This is achieved by using high efficiency methods, made possible because of improved tool life and cutting edge reliability.

72 new inserts have been added. These additions further extends the range of sizes of corner geometries, corner radii and chipbreakers available to allow wider range of applications.

Features of MC5005 and MC5015

- MC5005 achieves outstanding wear resistance by combining the latest coating technologies, an extra thick Al2O3 coating layer.

- The optimized crystal growth, Nano-Texture Coating Technology gives outstanding wear and chipping resistance.

- Proprietary TOUGH-Grip Technology prevents the delamination of the coating since the interface between the layers is controlled at the nano level, allowing the TOUGH GRIP layer extremely high levels of adhesion to prevent delamination.

- Chip breakers for cast iron turning are selectable according to the machining conditions. The chip breaker range is available from a sharp cutting edge type for low cutting resistance through to chip breakers focused on cutting edge strength for interrupted cutting of materials with scale.

MFE Solid Carbide Flat Bottom Drills for Counter Boring

The MFE drill is designed to provide flat bottom holes and achieves high efficiency drilling over various applications such as machining angled and spherical surfaces. It is also ideal for thin plate machining and due to its excellent chipping resistance it can reduce overall machining times.

Features of the MFE drill

- The new point thinning geometry ensures the sufficient space for evacuating chips as well as offering low thrust.

- The combination of different radii in the cutting edge geometry provides strength and excellent chip control.

- A gashed land (0 degree rake) provides excellent chipping resistance.

- Smooth edge surfaces provide reduced deflection and excellent positional accuracy.

New solid carbide TRISTAR drill series DVAS for general purpose

TRISTAR, is a new generation of drills that provides 3 strong advantages. DVAS is the first of the Tristar series, it is a range of small diameter drills with 5 technological features for FAST, RELIABLE and ACCURATE drilling. 60 items ranging from cutting diameter 1 mm to 2.9 mm have now been released.

Features of the DVAS range from the TRISTAR drill series

- TRI-Cooling Technology is the optimal shape of through coolant hole and can achieve more than double the conventional coolant discharge volume. This dramatically improves chip discharge and heat dissipation.

- The straight cutting edge and thinned point are connected with a smooth, curved geometry that significantly improves fracture resistance.

- The new point thinning breaks chips into the optimum shape for streamlined flow and achieves a much lower cutting resistance.

- Short drills employ a specially designed flute and taper neck that results in improving tool rigidity and better chip flow.

MMT series for precise and efficient threading

M-class inserts with 3-D chip breakers

Features

- Excellent chip control

- Prevents burrs and vibration

- With moulded identification markings for easy thread recognition

MIRACLE coated VP15TF has a good balance of wear and fracture resistance.

MIRACLE coated VP20RT exhibits excellent performance for stainless steel machining. These grades are suitable for a variety of workpiece materials.

Open Catalog

MVS Solid Carbide Drill WSTAR Drill Series

The existing MVS range for general use has received a favorable reception in the market place as a revolutionary next-generation drill that realizes stable machining over a wide range of work materials and applications.

To complement the existing sizes, the range has now been expanded to include small diameters of 1.0mm-2.9mm.

Features of the small diameter of the MVS, the solid carbide drill WSTAR drill series

- New straight cutting edge geometry provides extra edge strength that gives a highly stable drilling performance.

- New optimized flute geometry improves chip evacuation and prevents chip clogging when deep hole drilling.

- Double flute margins achieve the optimum balance and precision for a small diameter drill.

- Available in 0.1mm increments from φ1.0 to φ2.9.

- L/D=2 is availaible for pilot holes and L/D=7, 12, 20, 25, 30 are available as standard, thereby offering a deep hole drilling capability.

MVX Indexable Insert Drill Series

The existing MVX drill provides excellent economy due to the 4-corner insert design and achieves a high cutting performance as well as long tool life. This is due to the optimum positioning of the outer and inner inserts on the drill body. To complement the existing sizes, the range has been expanded to include smaller sizes, φ14 mm to φ16.5 mm.

Features of the MVX drill

- Optimum positioning of the outer insert and inner insert; A CVD coated grade with high wear resistance for the outer insert due to the higher cutting speeds and a PVD coated grade with high stability for the inner insert due to the lower cutting speeds, thereby achieving optimum balance and long tool life.

- Increased surface hardness of the tool body prevents abrasive damage caused by chip flow. Therefore, longer tool life of the body is achieved

- Chip evacuation when drilling deep holes is improved with specially designed through coolant holes that maintain coolant pressure.

Cermet Grade for Steel and Cast IronTurning NX2525

Cermet grades are ideal for finishing and light cutting due to their excellent in high temperature hardness when compared with cemented carbide. Additionally it is able to maintain high quality surface finishes.

NX2525 has highly hardened Ti compound particles within its microstructure therefore the grade has both excellent wear and fracture resistance properties.

To allow a wider range of chip control, the FY breaker for mild steel finishing, plus the SY breaker for light cutting and also the SA breaker for carbon and alloy steels light cutting have been added to the NX2525 range.

Features of FY, SY and SA breaker

- The new three breakers cover copying and back turning due to the wavy edge design.

- The FY breaker effectively controls adhesive chips and is suitable for finishing mild steel.

- The SY breaker effectively controls adhesive chips and is suitable for light cutting of mild steel.

- The SA breaker offers superior chip control at small depths of cut when light cutting carbon and alloy steels.

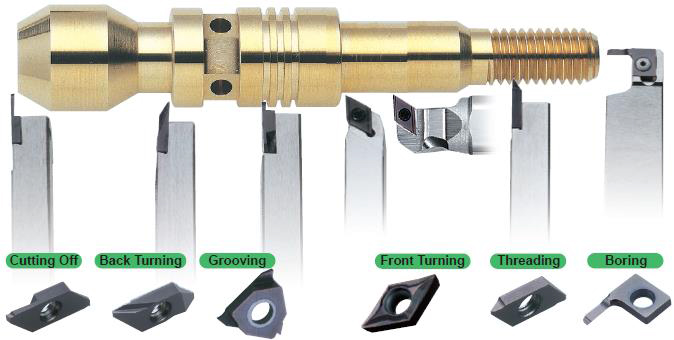

Tools for a Very Wide Range of Small Parts Machining

| External Turning | Tools for front turning, back turning, grooving, threading, and cutting off |

|---|---|

| Internal Turning | Tools for boring, internal grooving and internal threading |

| Drilling | Drills |

| End Milling | End Mills |

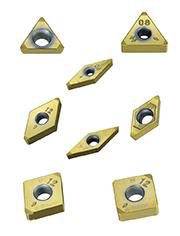

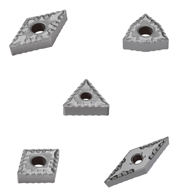

Indexable Inserts Developed Under the Concept of "High Quality, High Efficiency and Long Tool Life."

| High Quality | E class tolerance, sharp cutting edge, high accuracy small corner R, smooth surface finish |

|---|---|

| Long Tool Life | COATED CARBIDE (PVD) MS6015 / VP15F / MP9005 / MP9015 |

| High Efficiency | Regrinding not necessary due to the employment of indexable inserts. A wide variety of top cutting edge geometries |

Tools for CNC Automatic and Small Lathes

| Types of Tool Posts | Gang type, turret type, cam type(radial pattern type) |

|---|---|

| Tool Sizes | Square shank: 8–16 mm , Round shank : less than φ25.4 |

VPX Series Multi-functional Cutter for High Efficiency Machining

The VPX is a multi-functional cutter that provides high holder rigidity by arranging the inserts tangentially. This arrangement enables high efficiency for different types of milling such as ramping and helical milling under high-load conditions. Additionally, VPX provides excellent economy due to the indexable, double sided insert (4-corner inserts).

Features of the low resistance insert for VPX series

- The design featuring a sharp cutting edge achieves low cutting resistance

- The low resistance insert is suitable for mild steels, stainless steels, aluminium alloys and titanium alloys.

- 8 types of insert grades are available to cover a wide range of materials.

Double-sided Inserts for the WJX Series of High Feed Radius Milling Cutters

The WJX series is a range of double-sided insert radius cutters for high feed machining. The WJX cutter is especially suited for rough machining by incorporating the economics of negative inserts for high strength, but with a positive flank geometry that provides the ability for multi-functionality.

Main features of the WJX series.

- Provides low cutting resistance on entry to the workpiece and maintains stable machining even during interrupted, large depths of cut applications.

- A straight cutting edge extending to the maximum depth of cut allows for high feed machining even at large depths of cut.

- The dovetail structure prevents the insert from floating and provides stable clamping without using a clamp bridge.

- The unique cutting edge geometry forms short chips and helps to prevent chip tangling to further enhance usability and enables easy removal of chips from machine tools.

- Increased thickness prevents the inserts from fracturing and makes the cutter body resistant to breakage.

- The sharpness of the L type insert is best suited for extending tool life during stable machining of titanium alloys.

- The strong cutting edge R type insert improves fracture resistance during unstable machining.